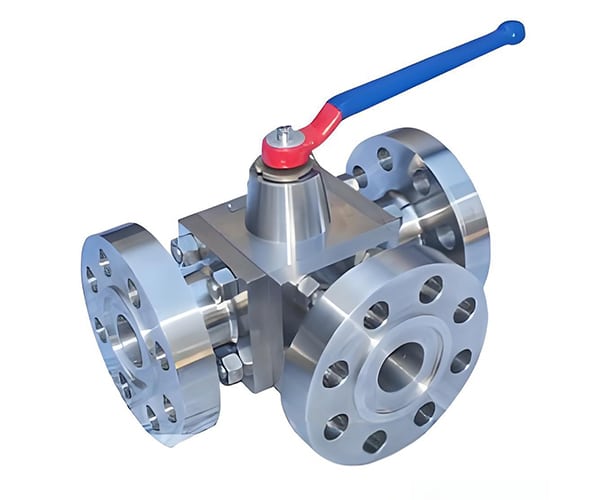

High pressure three-way ball valve

High pressure three-way ball valve

Product Overview | The High Pressure 3-Way Ball Valve is designed for applications that require high pressure handling and reliable diversion or mixing. Constructed from forged steel, the valve is capable of withstanding the extreme pressures found in high pressure systems, making it ideal for use in industries such as oil and gas, chemical processing, power generation and petrochemicals. The valve is capable of controlling the flow of liquids or gases between three ports for seamless diversion, mixing and distribution. The tee design provides flexible control and ensures that the valve can be adapted to a variety of complex piping systems. |

Product Features | FORGED STEEL CONSTRUCTION: Constructed of forged steel, this valve is designed for high-pressure applications and can withstand pressures up to 2,500 psi or more. Forged steel is known for its superior strength, durability and resistance to pressure cracking, making it the material of choice for high pressure applications. Three-Way Design: The valve utilizes a three-way ball valve design and is available in both L- and T-type configurations. the L-type ports are used to direct fluid between two outlets, while the T-type ports can be used to mix or divert fluid between multiple connections. This versatility is critical for complex flow control in a variety of industrial systems. SEALING PERFORMANCE: This ball valve utilizes a tight sealing mechanism that ensures zero leakage even under extreme pressure. The precision-machined ball and seat provide long-lasting performance and wear resistance even in harsh, high-pressure environments. Flange Connection: The valve is equipped with a flange connection that provides a safe and reliable seal, ensuring leak-free operation even in high-pressure, high-temperature environments. The flanged design is ideal for maintaining the integrity of high pressure systems and is easy to install and maintain. High-Temperature, High-Pressure Resistance: Designed for high-temperature, high-pressure systems, this valve can withstand temperatures up to 450°C and pressures up to 2,500 psi. It is designed to operate reliably under severe operating conditions where safety and reliability are critical. CORROSION AND ABRASION RESISTANCE: The valve is constructed of corrosion-resistant materials to withstand corrosive fluids, chemicals and abrasive substances. This ensures that the valve remains functional and efficient even when used in harsh environments such as refineries, chemical plants and natural gas pipelines. Wide range of applications: The three-way valve has a flexible design and is suitable for diverting, mixing and distributing liquids, gases and slurries. It is commonly used in piping systems that require precise flow control and distribution between multiple outlets. |

Product Advantages | Durable under high pressure: Forged steel construction ensures that the valve will perform well under extreme pressure conditions, providing excellent reliability and long service life even in the harshest environments. High-temperature and high-pressure resistance: Designed for safe operation in high-temperature systems, the valve maintains its integrity and performance even at extreme pressures and temperatures up to 450°C. The valve is designed to withstand high temperatures and to operate at high temperatures. Reliable, leak-free operation: Precision-machined seats and balls provide high sealing performance to prevent leakage in high-pressure systems. This ensures safety and system integrity in critical applications. Versatile Flow Control: The three-way design allows for efficient fluid diversion and mixing, enabling the user to precisely control flow and distribution, making it suitable for a wide range of applications. Corrosion and wear resistance: With its corrosion resistance, the valve is ideal for handling corrosive chemicals and media, ensuring long service life and minimizing downtime for repair or replacement. Easy to install and maintain: Flanged connections simplify installation and maintenance procedures, making the valve easy to integrate into high-pressure piping systems. |

Medium of use

working condition

summarize

Product Parameters

| Nominal diameter | DN15 (1/2") - DN300 (12") |

| Nominal pressure | PN10-PN63 (150lb-600lb) |

| Valve Type | Three-Way Ball Valves (L or T Model) |

| Valve Material | Forged steel (ASTM A105, F11, F22, F304, F316) |

| Applicable temperature | -20°C to 300°C |

| connection method | Flange connections (ANSI B16.5, B16.47, ASME) |

| Valve body type | Full Port, Tee (L-Port or T-Port) |

| Ball and Seat Materials | Forged steel, high performance seals |

High Pressure Three-Way Ball Valve Similar Products

The following are similar products. You can search for other related products.

節(jié)閥1.jpg)