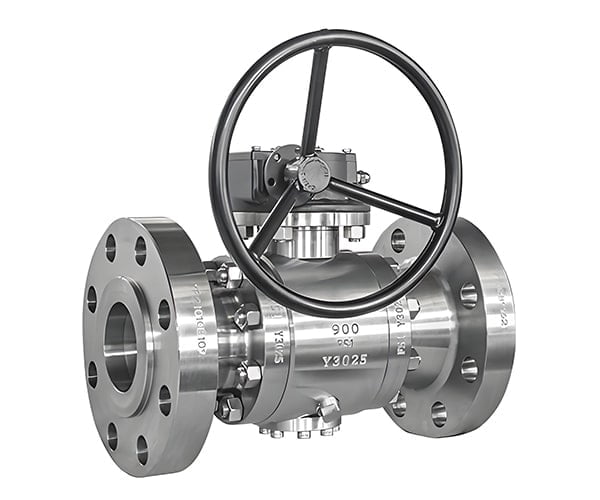

Forged Steel High Pressure Ball Valve

Forged Steel High Pressure Ball Valve

Product Overview | The Forged Steel High Pressure Ball Valve is a rugged, high performance valve designed to handle high pressure applications in industries where strength, durability and safety are critical. Constructed from forged steel, this valve is ideally suited for use in severe service at high pressures and extreme temperatures. It offers tight shutoff performance, excellent flow control, and is extremely resistant to wear, corrosion and fatigue. These valves are widely used in critical industrial applications such as oil and gas, chemical, power generation and water treatment systems. The valve features a float or trunnion-mounted ball design (depending on the pressure rating) to provide reliable flow control and minimize leakage even under the most severe conditions. Forged steel construction provides added strength and ensures that the valve can withstand high internal pressures without failure. Flanged or butt-welded connections ensure safe installation of the valve in high-pressure pipelines. |

Product Features: | FORGED STEEL CONSTRUCTION: This valve is made of high quality forged steel for superior strength and high pressure resistance. It is ideally suited for applications where the valve must withstand high mechanical stress and maintain structural integrity. High-Pressure Resistance: This valve is designed for high-pressure systems and is typically rated from 1500 psi to 4500 psi, depending on valve size and material. This makes it ideally suited for severe service where pressure is critical. Tight Shutoff: The valve utilizes a float or trunnion-mounted ball design for leak-free operation and tight shutoff, even at high pressures. This design is critical for applications requiring reliable fluid isolation, such as chemical plants, power plants, and oil and gas pipelines. Corrosion and abrasion resistance: Forged steel valve bodies offer excellent resistance to wear, corrosion and erosion, making them ideal for use in demanding environments where corrosive media may be present, such as in oilfields, refineries and the chemical industry. Flanged and welded connections: The valves are available with flanged or butt-welded connections for easy integration into high-pressure systems, ensuring safe leakage prevention and minimal maintenance requirements. LOW MAINTENANCE COSTS: Forged steel high pressure ball valves are designed for simplicity and durability with minimal maintenance requirements. Its rugged construction reduces the need for frequent repairs or replacement, extends service life and lowers operating costs. |

Product Advantages | Enhanced durability: Forged steel improves the mechanical strength of the valve, enabling it to withstand higher pressures and have a longer service life than cast steel valves under high pressure environments. Reliable performance at high pressures: Designed for high-pressure operation, this valve provides tight shutoff and controlled flow, which is critical for industries such as oil and gas, refineries and chemical processing. Leak-free operation: Floating ball or trunnion-mounted ball valves ensure minimal leakage even at high pressures, making them ideal for applications where safety and reliability are critical. Corrosion and abrasion resistance: High corrosion and abrasion resistance makes the valve ideal for handling corrosive media such as acids, alkalis and hydrocarbons, even in harsh environments for extended service life. Cost-effective: Although more expensive than other types of valves, forged steel high-pressure ball valves provide excellent value through their longer service life, lower maintenance costs and reliable performance in critical applications. Safety: Designed with safety in mind, this valve ensures reliable shutoff in high-pressure systems, thereby helping to prevent potential hazards and thus contributing to the overall safety of the operation. |

Medium of use

working condition

summarize

Product Parameters

| Nominal diameter | DN50-DN1200 (2"-48") |

| Nominal pressure | PN40-PN320 (300LB-2500LB) |

| Material | Forged Steel (A105, F11, F22, F304, F316, etc.) |

| Applicable temperature | -29°C to 300°C (customizable options) |

| connection method | Flange, Butt Weld |

| sealing material | PTFE, Viton, RTFE, PEEK, Hard Seal |

| leakage rate | ISO 5208 Class A (tightly closed) |

Forged Steel High Pressure Ball Valve Similar Products

The following are similar products. You can search for other related products.

節(jié)閥1.jpg)