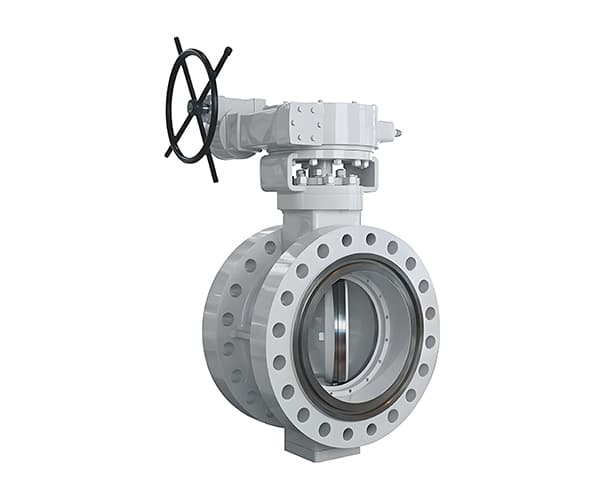

Bidirectional Metal Sealed Butterfly Valve

Bidirectional Metal Sealed Butterfly Valve

Product Overview | Bidirectional metal-sealed butterfly valve is a high-performance valve with excellent sealing performance, which is widely used in piping systems of petroleum, chemical, electric power, metallurgy, natural gas and other industries. The valve is suitable for water, oil, steam, gas and corrosive media, especially suitable for high temperature, high pressure and strong corrosive working conditions. Bidirectional metal seal design ensures that the valve can maintain reliable sealing in the case of bidirectional flow to prevent media leakage, and the sealing surface is not easy to wear. Product features include superior sealing performance, high temperature resistance, corrosion resistance, compact structure, rapid opening and closing, easy to operate, suitable for large flow and high pressure environment. The valve body adopts metal sealing structure, which ensures the stability under high temperature and high pressure working conditions, and can maintain efficient sealing even in harsh environments. Bidirectional metal-sealed butterfly valve is mainly used for cutting off, regulating and controlling fluids, which can ensure the stable operation of pipeline system, especially suitable for occasions requiring high sealing and bidirectional flow. Its excellent performance makes it an indispensable key valve equipment in industrial piping system. |

Product Features | Bi-directional seals: Designed to handle fluids in both directions and are suitable for complex piping systems. Metal Seal Technology: High-grade stainless steel or alloy metal seats are used to withstand high temperatures and abrasive media. Triple Eccentric Design: The use of triple offset mechanism eliminates friction between the valve flap and seat during operation, thus reducing wear and prolonging valve life. Durable construction: Body and flap materials include carbon steel, stainless steel, duplex stainless steel or alloy steel to ensure superior mechanical strength. Wide range of sizes and ratings: sizes from DN50 to DN1200 and pressure ratings up to PN40/ANSI 300. Flexible actuator options: Compatible with manual, pneumatic, electric or hydraulic actuators that can be integrated with automation systems for precise remote control. Low Maintenance Design: Frictionless operation minimizes sealing surface wear and reduces maintenance frequency and costs. |

Product Advantages | High reliability: Bi-directional seals ensure stable performance even under changing flow conditions. Cross-industry versatility: Suitable for a wide range of media including gases, vapors, oils, water and corrosive chemicals. Cost-effective solution: long service life, low maintenance requirements and reduced total cost of ownership. Environmentally friendly: Metal seals eliminate the need for soft seals, reducing waste and ensuring compliance with strict environmental regulations. |

Medium of use

working condition

summarize

Product Parameters

| Nominal diameter | 2- 48 inch; DN50-DN1200 |

| Nominal pressure | PN10-PN40,( 150LB-300LB ) |

| Valve Material | Carbon steel, stainless steel, duplex steel, alloy steel |

| Valve material | Carbon steel, stainless steel, duplex steel, alloy steel |

| sealing material | Metal seat (stainless steel or alloy metal) |

| Applicable temperature | -40°C to 450°C |

| connection method | Clamping, lug type, flange type, butt weld seam |

| leak rate | Class V or VI |

| actuators | Manual, pneumatic, electric, hydraulic |

| Standards Compliance | API 609, ISO 5752, EN 593, ASME B16.34 |

Bidirectional Metal Sealed Butterfly Valve Similar Products

The following are similar products. You can search for other related products.

閥1.jpg)