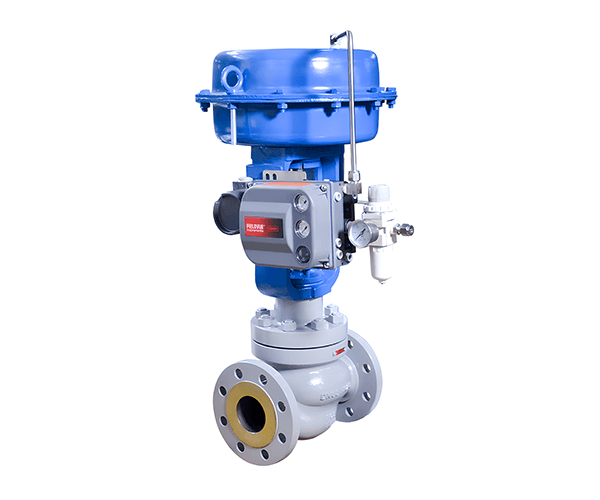

Pneumatic single seat adjustment valve

Pneumatic single seat adjustment valve

Product Overview | The Pneumatic Single Seated Control Valve is a high performance control valve designed to precisely control fluid pressure, flow or temperature. The valve is driven by a pneumatic actuator and utilizes a single-seated plug structure with a compact design, fast response and high reliability, making it suitable for use in harsh industrial environments such as oil and gas, chemical, power generation, etc., and is especially suited for explosion-proof applications. | ||||||||||||||||||

Applicable working conditions | Chemical industry: precise dosing and flow control of corrosive media (acids, alkalis). Oil and gas: pipeline pressure regulation and separator level control. Power systems: boiler feedwater and steam flow regulation. Pharmaceutical and food: aseptic fluid control and temperature regulation. | ||||||||||||||||||

Main features | Pneumatic actuators: Type: Spring-return diaphragm or piston actuator with fail-open (FO) or fail-closed (FC) mode. Single-seat valve design: High sealing performance: ANSI Class IV or Class VI leakage rates for critical shutdown applications. Flow characteristics: Linear, Equal Percentage, or Rapid Open valve internals options with customizable flow curves. Materials & Durability: Valve body materials: carbon steel (WCB), stainless steel (304/316L), duplex steel (UNS S32205). Compatibility: Signal inputs: 4-20 mA, 3-15 psi pneumatic; supports HART communications. | ||||||||||||||||||

Comparison of similar products |

| ||||||||||||||||||

Product Advantages | Fast response: millisecond adjustment by pneumatic drive. Explosion-proof safety: non-sparking design, ATEX/IECEx certified. Easy maintenance: modular design allows for quick spool and seal replacement. Cost-effective: Lower operating costs compared to motorized valves. | ||||||||||||||||||

Medium of use

working condition

summarize

Product Parameters

| Nominal diameter | DN15-DN200 (?"-8") |

| Nominal pressure | PN16-PN100 / Class 150-600 (ASME B16.34) |

| Applicable temperature | -40°C to 450°C (depending on seal) |

| leakage rate | ANSI Class IV (standard) / Class VI (optional) |

| Supply pressure | 0.14-0.7 MPa (20-100 psi) |

| response time (technology) | 1-5 seconds |

| connection method | Flange (RF/RTJ), Socket Weld (SW) |

Pneumatic Single Seat Adjustment Valve Similar Products

The following are similar products. You can search for other related products.

閥1.jpg)