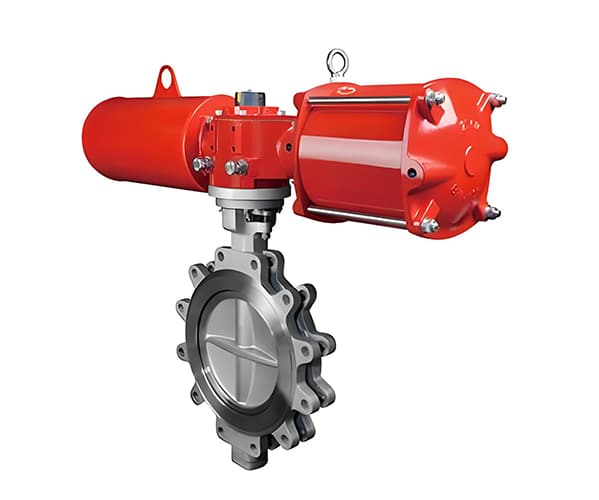

Pneumatic hard seal butterfly valve

Pneumatic hard seal butterfly valve

Product Overview | The Pneumatic Hard Seal Butterfly Valve is a high performance valve designed for reliable operation in demanding industrial applications. It combines a rugged metal-sealed construction with the precision and convenience of a pneumatic actuator, making it ideal for applications requiring resistance to high temperatures and pressures as well as tight shutoff performance. The valve features a triple eccentric (triple offset) design that ensures zero leakage and reduces sealing surface wear, resulting in longer service life. The hard sealing mechanism is typically made of stainless steel or alloys, providing excellent durability and corrosion resistance even in corrosive media. A pneumatic actuator allows for quick automated operation, making the valve suitable for processes requiring precise flow control and automation. |

Main performance | Hard seal structure: The valve adopts metal-to-metal seal design to ensure excellent performance even under high temperature and high pressure environments. Pneumatic actuation: The valve is equipped with a high-quality pneumatic actuator for fast and reliable operation, suitable for frequent switching cycles. Wide selection of materials: Body and flapper materials include carbon, stainless (304, 316, or 316L), and alloy steels to ensure suitability for a wide range of conditions. Seal materials can be customized to meet specific application requirements and include Stellite, hard chrome plating or nickel-based alloys. High durability: The valve's hard seal design ensures good wear resistance even under severe conditions such as high flow rates or abrasive media. Compact and versatile: The compact design and lightweight construction make it easier to install and integrate into existing piping systems. Precise flow control: The combination of hard seals and pneumatic actuation allows for highly accurate flow control, enabling precise regulation in critical industrial processes. |

Product Advantages | High-temperature and high-pressure resistance: The valve is metal-sealed and can operate at temperatures up to 350°C and pressures up to PN40 for demanding applications. Corrosion and wear resistance: Corrosion-resistant materials such as 316 stainless steel or hard-coated alloys are used to ensure durability in harsh environments such as chemical and petrochemical. Rapid automation operation: pneumatic actuators can be quickly opened and closed, significantly increasing the process efficiency of automated systems. Low Maintenance Requirements: The triple eccentric design minimizes wear and reduces the need for frequent maintenance, helping to reduce operating costs. Wide range of applications: suitable for handling various media, including steam, gas, oil and corrosive chemicals, for power generation, metallurgy, petrochemical and water treatment industries. |

Medium of use

working condition

summarize

Product Parameters

| Nominal diameter | 2-64 inch; DN50-DN1600 |

| Nominal pressure | PN10-PN40; (150LB-300LB) |

| Valve Material | Carbon steel, stainless steel (304, 316, 316L), alloy steel |

| sealing material | Metal-to-metal (Stellite, chromium, nickel-based alloys) |

| temperature range | -40°C to 350°C |

| connection method | Clamping type, lug type, flange type |

| actuators | Pneumatic (spring return, double acting) |

| control method | On/Off, Adjustment |

Pneumatic Hard Seal Butterfly Valve Similar Products

The following are similar products. You can search for other related products.

節(jié)閥1.jpg)