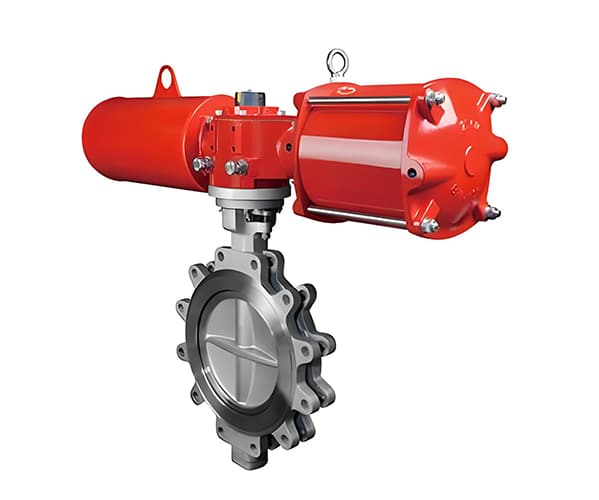

Pneumatic High Performance Butterfly Valve

Pneumatic High Performance Butterfly Valve

Product Overview | Pneumatically operated high performance butterfly valves are designed for industrial applications requiring superior sealing performance, high flow efficiency and precise control. The valves feature a double eccentric (two eccentric) or triple eccentric (three eccentric) design to minimize wear and achieve a tight seal even under high pressure and high temperature conditions. Driven by a pneumatic actuator, the valve operates quickly and reliably, which is essential for applications requiring frequent opening and closing or automated control. The combination of advanced sealing technology and high quality materials ensures durability and long term performance in a variety of industrial environments. |

Main characteristics | High-performance design: Double or triple eccentric structure: Reduces friction between valve flap and seat during operation, ensuring longer service life and superior sealing performance. Bi-directional sealing: Enables the valve to maintain a tight seal in both flow directions, enhancing safety and flexibility. Pneumatic Drive: Equipped with reliable pneumatic actuators to support fast response and precise control. Available in spring-return or double-acting configurations for a variety of control options. Compatible with a variety of control systems, including on/off, modulating and fail-safe modes. Quality materials: Valve body materials include carbon steel, stainless steel (304, 316, 316L), and alloy steel to meet a variety of operating conditions. Seat materials (such as PTFE, graphite or metal alloys) ensure compatibility with a wide range of media, including abrasive and corrosive substances. Superior sealing performance: Zero leakage (Class VI) or hermetic sealing is achieved, making it suitable for critical processes with high integrity requirements. Compact and lightweight design: Easier to install and maintain than other types of valves, compact profile saves space in piping systems. Connection options: Available in clamp, lug and flange configurations for flexible integration into a variety of piping systems. |

Product Advantages | Enhanced Durability: Offset design and high quality materials ensure minimized wear and prolonged service life, even under harsh conditions. High efficiency: Streamlined valve flap and low pressure drop design improves flow efficiency and reduces system energy consumption. Precise Control: Pneumatic actuators provide precise and repeatable control, ideal for automated systems in industries that require tight flow control. Resistant to extreme conditions: Reliable operation in high-pressure, high-temperature environments, withstanding temperatures up to 600°C and pressures up to PN40. Low Maintenance Requirements: The durable construction of the sealing surfaces and the self-cleaning feature reduce maintenance frequency and associated costs. Versatility: Suitable for a wide range of media in a variety of industries, including steam, gases, oils, chemicals and slurries. |

Medium of use

working condition

summarize

Product Parameters

| Nominal diameter | 2- 48 inch; (DN50-DN1200) |

| Nominal pressure | PN10-PN40 , ( 150LB-300LB ) |

| Valve Material | Carbon steel, stainless steel (304, 316, 316L), alloy steel |

| sealing material | PTFE, graphite, metal alloys |

| temperature range | -40°C to 350°C |

| connection method | Clamping type, lug type, flange type |

| actuators | Pneumatic (spring return, double acting) |

Pneumatic High Performance Butterfly Valve Similar Products

The following are similar products. You can search for other related products.

多孔低噪音調(diào)節(jié)閥1.jpg)