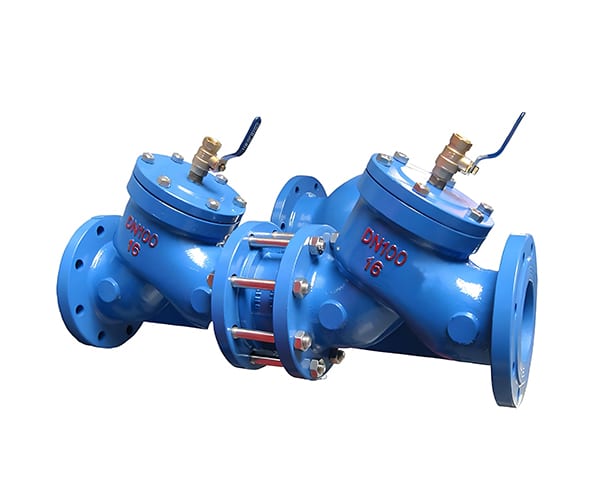

Double check backflow preventer

Double check backflow preventer

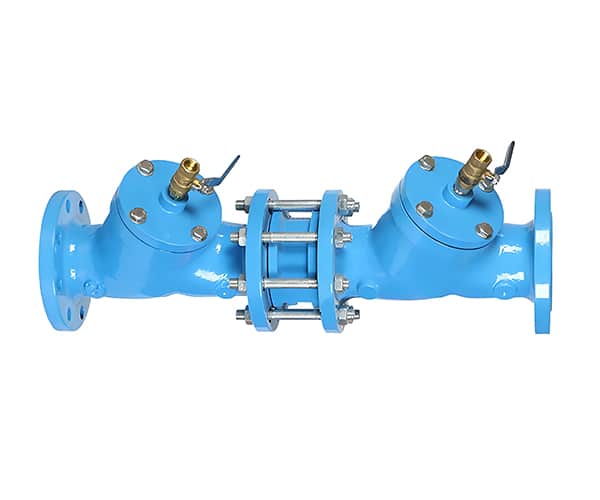

Product Overview | Double check backflow preventer is an efficient equipment to prevent fluid backflow, widely used in drinking water, fire fighting system, industrial pipeline and sewage treatment and other fields. The equipment is mainly used to prevent backflow of water in water supply pipelines, to avoid contamination of water sources or harmful substances in the system backflow back to the water supply network, to ensure the safety of water quality. It is suitable for piping systems of water, sewage, oil and slightly corrosive liquids. The Double Check Backflow Preventer doubly protects the piping system by means of two independent check valve assemblies. Once backflow is detected, the two check valves will automatically close, effectively preventing backflow from occurring. Product advantages include compact structure, superior sealing performance, sensitive response, low flow resistance, and is suitable for a variety of water quality environments. The equipment is made of corrosion-resistant materials to ensure that it maintains efficient performance in long-term use. The main function of the double check backflow preventer is to safeguard the safety of the water source and piping system, and to prevent pollution sources from entering the water supply system. Widely used in the need to prevent backflow and water quality protection occasions, is to ensure that the water supply system healthy and reliable operation of the ideal equipment. | |||||||||||||||

Main characteristics | Dual check valve design: First check valve: prevents backflow under atmospheric conditions. Second check valve: acts as a backup barrier in case of failure of the first check valve. Pressure relief chamber (optional): automatically relieves intermediate pressure to prevent contamination. Low resistance to flow: optimized flow path minimizes pressure drop (Cv ≥ 1.2 at DN50). Ideal for high-flow systems requiring energy savings. Durable materials: Bronze (C83600): lightweight and corrosion-resistant for general use. Stainless Steel (304/316L): Excellent resistance to chlorides and acids. Ductile Iron (EN-GJS-400-18): Heavy duty construction for industrial applications. Compliance and Safety: Complies with ASSE 1015, EN 1717 and ISO 5208. Leakage class VI (zero leakage under test conditions). Ease of Maintenance: Modular design allows for quick inspection and seal replacement. Test plugs that can be field tested without disassembly. | |||||||||||||||

Product Advantages | Fail-safe: Dual check valves provide redundant protection against backflow. Energy saving: low pressure drop, reducing the load on the pump. Versatile: Suitable for water, air and non-corrosive fluids. Compliance Ready: Pre-certified for global regulatory requirements. | |||||||||||||||

Comparison of similar products |

| |||||||||||||||

Medium of use

working condition

summarize

Product Parameters

| Nominal diameter | DN50 to DN300 (2" to 12") |

| Nominal pressure | PN10 to PN25 (EN 1092) / Class 150 to 300 (ASME B16.34) |

| Applicable temperature | -20°C to 120°C (EPDM seals) |

| Valve Material | Bronze (C83600), 304/316L stainless steel, ductile iron (EN-GJS-400-18) |

| sealing material | EPDM, NBR, or PTFE (FDA-compliant options available) |

| connection method | Flanges (EN 1092/ASME B16.5) |

Double Check Backflow Preventer Similar Products

The following are similar products. You can search for other related products.

閥1.jpg)