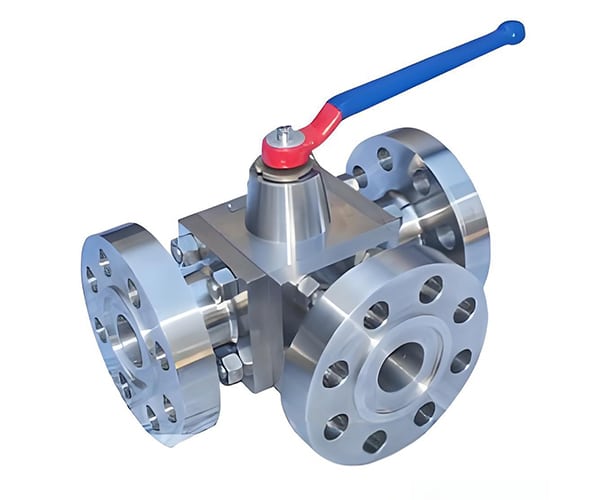

Cryogenic three-way ball valve

Cryogenic three-way ball valve

Product Overview | The Cryogenic 3-Way Ball Valve is a high performance valve designed to operate efficiently in extremely low temperature environments, typically in the range of -196°C to -40°C. These valves are essential for applications in industries such as liquefied natural gas (LNG), cryogenics, refrigeration, and oil and gas that require precise control of flow or mixing at extremely low temperatures. The valve's three-way ball design provides flexible fluid diverting or mixing between three different ports, ensuring smooth and reliable operation in harsh cryogenic conditions. Manufactured with high quality materials and specialized sealing technology, the Cryogenic 3-Way Ball Valve provides excellent resistance to thermal expansion, material embrittlement and valve leakage in cryogenic applications. It ensures that systems operating at very low temperatures maintain optimum flow control while preventing leakage or failure that could jeopardize safety and efficiency. |

Product Characteristics | Low Temperature Adaptability: Designed to withstand extreme cold temperatures from -196°C to -40°C, the valve maintains structural integrity and sealing performance at low temperatures, making it ideally suited for low temperature applications. Three-Way Flow Control: The valve features a three-way ball design and is available in both L-port and T-port configurations. the L-port is used to direct fluid between two outlets, while the T-port is used to mix or transfer fluid between the three ports, providing flexibility in controlling the flow or mixing of fluid. the L-port is used to direct fluid between two outlets, while the T-port is used to mix or transfer fluid between the three ports. HIGH QUALITY MATERIALS: The valve is made of cryogenic grade stainless steel and is constructed to ensure durability and performance in cryogenic systems. Materials such as 316L stainless steel or special alloys are often used to prevent embrittlement and ensure that the valve does not lose strength at low temperatures. Specialized seals and seats: The valves are equipped with cryogenic seals made of materials such as PTFE (polytetrafluoroethylene), PFA (perfluoroalkoxy), or Viton, which provide excellent sealing performance, even in extremely cold conditions. These seals are engineered to prevent leakage in cryogenic systems, ensuring system integrity. Leak-free performance: The valve is designed with a float mechanism for superior sealing performance that prevents leakage at low temperatures where other materials may become brittle or fail. The seat design also provides excellent sealing performance even under extreme heat conditions. Compact and lightweight design: The valve's compact and lightweight design makes it easy to install and saves space, which is critical in environments where weight and space are critical. Flanged or threaded connections: The valves are equipped with flanged or threaded end connections to ensure secure installation in a variety of piping systems. Flanged connections provide high-pressure performance and easy maintenance, while threaded connections are suitable for smaller sizes or space-constrained applications. |

Product Advantages | Superior cryogenic performance: The valve is designed for cryogenic systems to ensure reliable operation at very low temperatures, ensuring that your system is capable of fluid control under the harshest conditions. Versatile Flow Control: The 3-way ball valve is designed for flexible control of flow or mixing of fluids. It is ideal for applications that require switching flow paths or mixing different fluids at low temperatures. Enhanced safety: The valve's robust construction and high-performance seals ensure leak-free operation even in extremely cold environments, providing additional safety for critical applications such as liquefied natural gas (LNG) storage and transportation. DURABLE AND RELIABLE: The use of low-temperature grade materials and high-quality seals ensures the life and reliability of the valve, even under severe operating conditions. It prevents thermal expansion and material embrittlement, thus ensuring long-term performance. Easy to install and maintain: flanged or threaded connections make installation and maintenance easier, and the compact design makes it easy to operate in tight spaces or confined environments. Corrosion resistance: Stainless steel construction and cryogenic grade seals provide excellent corrosion resistance, making the valve suitable for corrosive fluids or corrosive environments such as cryogenic tanks and pipelines. |

Medium of use

working condition

summarize

Product Parameters

| Nominal diameter | DN15 (1/2") - DN300 (12") |

| Nominal pressure | PN10-PN63 (150LB-600LB) |

| Valve Type | Three-Way Ball Valves (L or T Model) |

| Valve Material | Low temperature grade stainless steel (316L, alloy C-276, etc.) |

| Applicable temperature | -196°C to -40°C |

| connection method | Flanged or threaded (ANSI B16.5, ASME B16.47) |

| sealing material | PTFE, PFA, Viton, EPDM |

| Sphere form | Floating or fixed ball |

Low Temperature Three-Way Ball Valve Similar Products

The following are similar products. You can search for other related products.

節(jié)閥1.jpg)